Mechanical regeneration

This means mechanically removing efficiency reducing deposits from the well annulus and the adjacent aquifer with the aim of restoring the hydraulic function.

During the entirely mechanical regeneration, the separation process takes places entirely without using any chemical substances.

Blast pulse method

Two pairs of blast pipes rotating in opposite directions are operated by means of high-pressure water. These blast pipes introduce into the well system (including the adjacent aquifer) the energy required for removing und separating the soilings and siltings. At the same time, the dissolved substances are discharged and the data are captured continuously thereby guaranteeing a best-possible regeneration of the well.

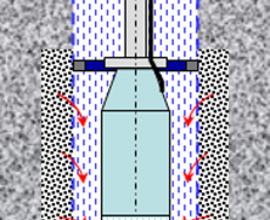

Heavy-duty removal of sandy deposits

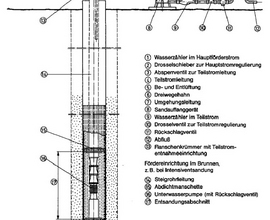

Hydromechanical regeneration

A hydromechanical well regeneration needs to be done whenever slightly or severely solidified deposits are present in the annulus. Currently, a hydromechanical regeneration can be carried out via various different methods. Depending on the nature of the deposits, a heavy-duty withdrawal, a low-pressure interior flushing or the already mentioned high-pressure flushing procedure will be applied.